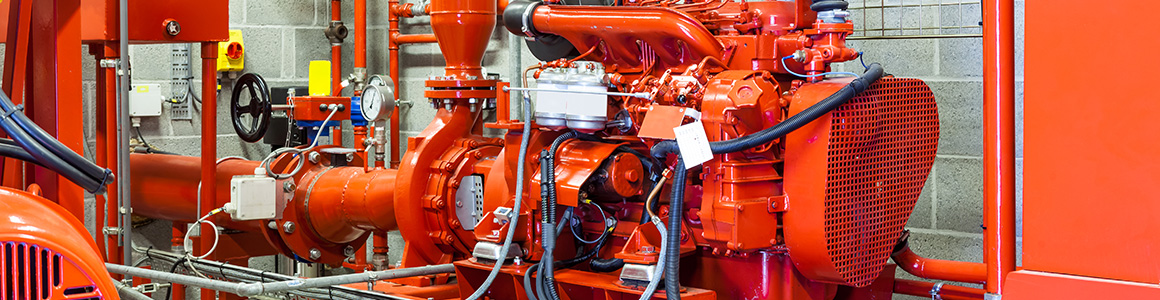

Power continuity from generators and UPS systems provide a critical supply of electricity in the event of disruption. Generators typically rely on fuels such as diesel or bio-diesel. This is usually stored on site and pumped to the generator when required. The tanks, pipework and the generator itself are all at risk from failure.

Generator and tank rooms are vulnerable due to their location; locked away in basements and areas of the building which are not inspected frequently. Small or large spills can easily go un-noticed.

Three sensing devices utilising different technologies are available for these applications.

The AquiTron optical liquid sensor (AT-OPSEN) is able to detect many fuels and oils associated with generators and day/bulk storage tanks within commercial buildings. Diesel, bio-diesel, kerosene, hydraulic oil and liquid coolants contained within radiators and cooling systems on generators can all be detected. The sensor is fast acting and can be re-set in seconds for immediate re-use.

The sensor can be positioned on the floor below the generator, under day tanks, and within trenches and sumps. A version is available that can be screwed into the outer wall of pipe-in-pipe systems (double contained pipe or double skin tank) to detect leak from the primary containment.

The TraceTek Fast Fuel Sensor probe (TT-FFS) is capable of reacting to the presence of diesel (or any hydrocarbon fuels including bio-diesel) within a few seconds.

TT5000 sensor cable can monitor hundreds of metres of pipework and provide the same precise leak location information that is the feature of all TraceTek cables.. It can also be buried in the ground for pipe runs from the external bulk fuel tanks to within the building.

Both the TT5000 and the TT-FFS can be used both internally and externally as they are not affected by the presence of water.